Case Studies

Project Success Stories

At 10/6, we measure success through the lasting impact of our projects. From modernizing critical utility infrastructure to delivering sustainable transportation solutions, our case studies demonstrate how precision project management drives exceptional results. Explore how we’ve helped clients maintain under 5% forecast variance, meet aggressive timelines, and advance sustainability goals across complex capital projects.

Transmission Line (T-Line) Capital Project

When it comes to powering your project during a planned clearance, generators can quickly rack up costs of over $10k per day. That’s why our project managers (PMs) prioritize safety and cost-effectiveness to provide our clients with the best possible service. We explore opportunities for pre-clearance work and consider pre-fabricating or partially constructing equipment to minimize costs and reduce the clearance window.

More...

We believe that strong communication lines are crucial to managing the generation effort efficiently and ensuring that your project is completed on time.

Recently, we worked on a challenging electric distribution pole replacement project in the foothills. The project required temporary generation at the same two substations as our client’s project, scheduled for early 2018. Rather than work separately, we recognized the opportunity for collaboration and coordination with the other project team.

While there was a slight risk of delay due to drilling difficulties, our PM’s schedule adjustment resulted in over $1M in cost savings by completing the work in the Fall of 2018 and sharing the cost of temporary generation and construction crews.

At 10/6 Professional Services, we don’t just manage projects – we go above and beyond to provide exceptional service and innovative solutions. We take pride in helping our clients achieve their goals and save money in the process.

T-Line Supervisory Control and Data Acquisition (SCADA) Program Management

At 10/6, we’re not afraid to roll up our sleeves and get into the details. For a recent SCADA project, we put together a dream team consisting of a Scheduler and Project Controls Analyst (PCA) to manage the project from start to finish. We worked closely with contractors to standardize submissions, automate reports, and integrate submissions with existing reports.

More...

Using our expertise in automation, we built reports to capture P6 schedule data from the contractor schedules and populate the metric milestones per region. Our Scheduler and PCA also integrated resource management and tracking tools into the report. They created engineering and construction dashboards utilizing the contractor P6 schedules to summarize month-over-month data for each Engineering, Procurement, and Construction (EPC) vendor for the PG&E key milestones.

The results were staggering – decreased human performance errors and major cost savings through the automation of manual reporting. We know that avoiding manual reporting at the earliest possible program stage is key to keeping costs down. For instance, before our team stepped in, each EPC contractor spent two hours per week on average generating engineering updates manually, with the Utility spending another four hours per week manually capturing those updates and combining them all under an Excel sheet. Over the course of one year, that’s 520 hours of wasted time and money.

But with our automation efforts, we saved $110K per year for engineering reporting alone – just imagine the savings from automating all the reports and data requests needed daily! At 10/6, we believe in working smarter, not harder. Let us show you how we can help your project run more efficiently and cost-effectively.

Coal Ash Removal at Decommissioned Power Plants

A major utility in a southeastern U.S. state of coal ash ponds wanted to clean up 12 coal ash ponds at decommissioned power plants. Our team provides oversight, identifies improvement opportunities, and ensures consistency across all sites. By removing toxic coal ash, we aim to protect the environment, prevent pollution, and safeguard public health.

MORE...

The initiative focuses on the remediation of coal ash ponds resulting from the decommissioning of 12 coal-fired power plants in a southeastern U.S. state. Our role is to provide additional oversight in terms of costs, schedule, risks, and change management. We aim to identify opportunities for improvement, conduct in-depth reviews of project variances, and offer recommendations to enhance consistency across all sites.

We conduct monthly site visits to meet with on-site project teams and discuss the progress of the work. Our team submits a monthly assessment report to the local power company, outlining observations and control analyses for each site to help identify trends, challenges, and achievements. The ultimate goal is to keep the project on schedule and within budget.

The project has significant environmental implications as coal ash contains a toxic mix of mercury, cadmium, arsenic, and other heavy metals. This waste can pollute waterways, endanger wildlife, and cause respiratory illnesses for those living nearby large storage ponds.

The process of coal ash removal mitigates both groundwater pollution sources and the risk of catastrophic spills resulting from containment failures due to extreme weather events such as floods. By cleaning up these coal ash ponds, the project aims to have a positive impact on the environment and the well-being of surrounding communities.

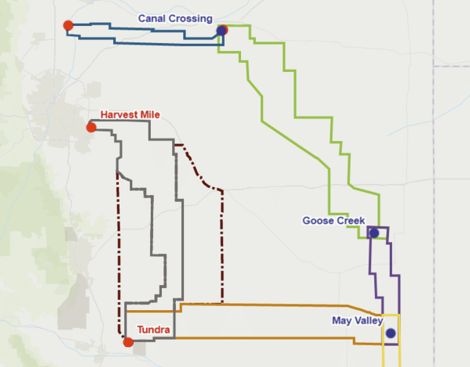

Empowering Economies through Sustainable Energy Infrastructure

A major Western Public Utility embarked on an ambitious project to set up 500 miles of renewable power infrastructure, aiming to boost the rural economy while meeting their decarbonization targets. With an aggressive timeline of being in service by 2025, the $1.8 billion renewable energy program was identified to enhance electric reliability by 2030, in accordance with US guidelines, and achieve state decarbonization goals.

MORE...

To ensure a successful implementation of the project, the public utility collaborated with 10/6, which provided a dedicated Project Management Office (PMO) team for risk assessment, cost controls, and scheduling for the multi-billion dollar portfolio. 10/6 leveraged a dual cost and schedule analyst model to keep costs and dates aligned, offering proactive portfolio analysis to manage monthly cash flow. Additionally, a standalone program was introduced to pilot cutting-edge processes, tools, and methodologies, along with program-level reporting for senior leadership.

The strategic partnership with 10/6 proved to be highly effective, resulting in a low monthly forecast variance of around 1%, serving as a powerful driver of achieving annual spending targets. The strong collaboration and commitment to innovation enabled the Western Public Utility to progress steadily toward their goal of setting up a robust renewable power infrastructure to support the rural economy and achieve their decarbonization targets.

This project highlights the importance of strategic planning, effective partnership, and innovative approaches in achieving complex, large-scale infrastructure projects. The project not only aligns with the utility’s decarbonization goals but also serves as a model for other public utilities and private entities looking to transition towards sustainable energy sources. By demonstrating the feasibility and benefits of such large-scale infrastructure projects, partnership with 10/6 sets the stage for further innovation and investment in renewable energy, fostering a greener, more prosperous future for all.